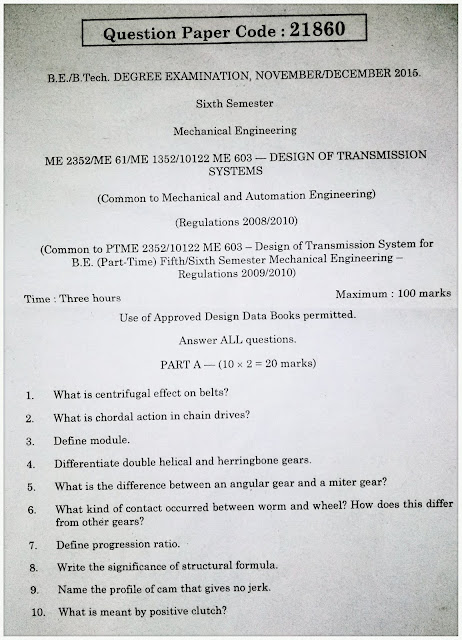

Question paper code: 21860

B.E/B.Tech Degree Examination, November/December 2015

Sixth semester

Mechanical Engineering

Click to download: ME6602 Automobile Engg Unit wise important university questions

Click ME6602 Automobile Engg Anna University Question April May 2014

ME 2352- Design of transmission systems

Click ME6602 Automobile Engg Anna University Question April May 2014

ME 2352- Design of transmission systems

(Common to Mechanical and Production Engineering)

Use of approved design data books permitted.

Click : DME Unit 2 Question Bank

Click: DME Unit 3 Question bank

Click: DME Unit 4 Question Bank

Click: DME Unit 5 Question Bank

Click: DME Unit 3 Question bank

Click: DME Unit 4 Question Bank

Click: DME Unit 5 Question Bank

Exercise problems based on Gear box, Clutches and Brakes

1.A single plate clutch transmits 25 kW at 900 rpm. The maximum pressure intensity between the plates is 85 kN/m2. The ratio of radii is 1.25. Both the sides of the plate are effective and the coefficient of friction is 0.25. Determine (i) the inner diameter of the plate (ii) axial force to engage the clutch. Assume theory of uniform wear.

2.A hydraulically operated clutch is to be designed for an automatically operated lathe. Determine the number of plates and the operating force required for a clutch which is to transmit a torsional moment of 35 Nm under normal operating conditions. The clutch is to be designed to slip under 300 percent of rated torsional moment to protect the gears and other parts of the drive. The limits for the diameters of the friction surface due to space limitations are 100 mm and 62.5 mm. This clutch is to operate in an oily atmosphere.

3.Design a 18 speed gearbox for a spindle of milling machine. Maximum and minimum speeds are 650 rpm and 35 rpm respectively. The drive is from an electric motor giving 3.75 kW at 1440 rpm.

4.Design a 12 speed gearbox for an all geared head stock of a lathe. Maximum and minimum speeds are 600 rpm and 25 rpm respectively. The drive is from an electric motor giving 2.25 kW at 1440 rpm.

5.A friction clutch is used to rotate a machine from a shaft rotating at a uniform speed of 250 rpm. The disc type clutch has both of its sides effective, the coefficient of friction being 0.3. The outer and inner diameters of the friction plate are 200 mm and 120 mm respectively. Assuming uniform wear of the clutch, the intensity of pressure is not to exceed 100 kN/m2. If the moment of inertia of the rotating parts of the machine is 6.5 kg-m2, determine the time to attain the full speed by the machine and the energy lost in slipping of the clutch. What will be the intensity of pressure, if the condition of uniform pressure of the clutch is considered? Also determine the ratio of power transmitted with uniform wear to that with uniform pressure.

6.A power of 20 kW is to be transmitted through a cone clutch at 500 rpm. For uniform wear condition, find the main dimensions of clutch and shaft. Also determine the axial force required to engage the clutch. Assume coefficient of friction as 0.25, the maximum normal pressure on the friction surface is not to exceed 0.08 MPa and take the design stress for the shaft material as 40 Mpa.

For more previous years university questions for all subjects go to : annaunivstudymaterials.blogspot.com

No comments:

Post a Comment